If you have a raised back door, front door, or side entrance into your mobile home, you will need a good set of mobile home steps to get in and out safely. Currently, there are four basic ready-made stairways for mobile homes: wood, metal, concrete, and fiberglass. The right type of staircase can provide easy access and dramatically improve the look of a home. But with so many options on the market, where and what should you look for in ready-made options? Here is what you need to know about mobile home steps before buying.

If you have a raised back door, front door, or side entrance into your mobile home, you will need a good set of mobile home steps to get in and out safely. Currently, there are four basic ready-made stairways for mobile homes: wood, metal, concrete, and fiberglass. The right type of staircase can provide easy access and dramatically improve the look of a home. But with so many options on the market, where and what should you look for in ready-made options? Here is what you need to know about mobile home steps before buying.

Mobile Home Steps or Stairs?

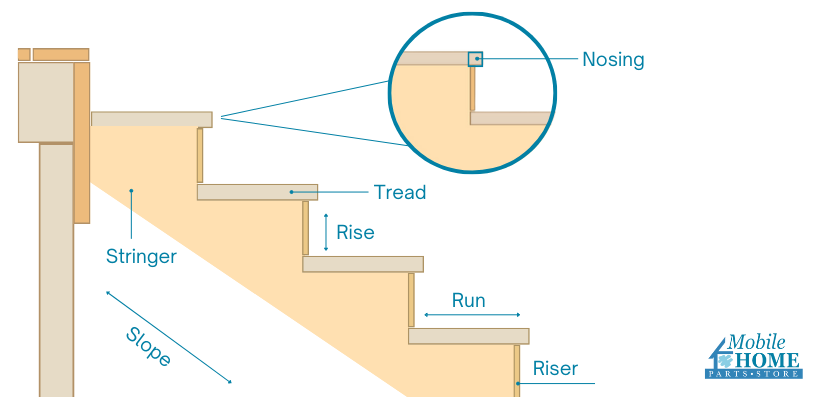

While we usually use the terms steps and stairs interchangeably, there is a difference between the two. Steps typically involve three or fewer risers, whereas stairs have four or more. Understanding the height of your raised back door, front door, or side entrance will help determine whether you should be looking for mobile home steps or stairs. However, you’ll need to know what a riser is to understand this difference more clearly. Let’s look at the basic terms used when discussing steps or stairs.

Mobile Home Steps and Stairs Basic Terms

Before we look at different types, you will want a basic understanding of essential terms when discussing steps or stairs.

Rise and Run

Rise and Run

The rise and run of mobile home steps are essential to understand before ordering. The rise and run determine the vertical and horizontal depth of each step. Rise is the vertical height or space from step to step, while the run is the step’s horizontal depth from riser to riser. The rise and run height will need to follow your local code. However, the standard size for the rise is around 7 ¾”, and typically, the run must be approximately 8 ¼” to 9”.

Stringer

A stringer is the vertical support board that runs along each side and center of the wooden steps or staircase. Typically the treads and risers are sized into the stringer. The number of stringers required is determined by the width of the stairs and the tread material.

Slope

The slope of steps or stairs is the angle of the steps. Therefore, when creating your stringers, you must know precisely the cuts you will be making. The ideal slope is 30-35 degrees. However, steep stairs can vary between 50-70 degrees.

Tread

Stair tread is the horizontal portion of a set of stairs on which a person walks. Your local code will also regulate the depth, width, and length of the step’s tread. However, it is usually around 1” -1 ¼” thick and 10 ½”- 11 ½ wide.

Nose

Nosing is the protruding edge of the tread over the riser. It should not protrude more than 1”.

Parts of Mobile Home Railings

Mobile home step railings have several parts that help keep them sturdy and safe:

Banister or Railing

The banister or railing is the horizontal support bar a person holds onto as they walk up and down the stairs. Typically local code requires a minimum of at least one handrail to be present on steps with four risers or more. Your local code will also determine the height of the railing; however, it is usually around 34”.

Vertical Posts

These vertical bars connect the handrail to the ground or the steps, providing stability and support for the handrail. Base plates secure the bottom of the vertical posts to the steps or ground. Balusters are the vertical bars between the top and bottom rails. They help prevent people from falling through the railing while still allowing visibility.

Railing Cap

These are covers placed on the ends of the handrail and sometimes on the tops of the vertical posts for safety and aesthetics.

Types of Mobile Home Steps

The top four materials for mobile home steps are wood, metal, concrete, and fiberglass. Let’s dig into the advantages and disadvantages of each material.

1. Wood

Wooden stairs are the most convenient material when building your mobile home steps. Wood is, for the most part, easy to get and is still reasonably affordable even with the increased cost of lumber in 2020.

However, they are susceptible to water damage, rot, and insects. Therefore, you will need to consider the weather if you live in a humid or rainy climate. Untreated stairs are susceptible to rot and swelling, significantly degrading their lifespan. In addition, you will need to invest in a concrete or composite pad underneath your steps or staircase to prevent the supports from sinking or becoming water damaged.

When considering building your mobile home steps with wood, finding the correct type of wood is essential. Weight, durability, insect and waterproofing, staining, and longevity are important aspects to consider when selecting lumber.

2. Metal

Another favorite material for mobile homeowners is metal. Metal mobile home steps are lightweight and easy to set up or break down, requiring only a few screws to construct.

Metal is a long-lasting and affordable choice for mobile home steps, but it can rust easily. Therefore, they should not be used as a permanent solution though they are a great temporary use for an RV.

3. Concrete

A popular choice for mobile homes and traditional home steps is concrete. A considerable advantage of concrete is its longevity. Once installed, they will last for years.

However, there are disadvantages to using concrete. Concrete is more expensive, weighs a ton, and requires a lot of ground preparation to level the steps. You will likely require a machine such as a forklift or a hoist if there are more than three steps. Even when the concrete stairs settle, they can become unleveled, weather, and chip over time. While the integrity of the stairs will always remain, the cosmetic appearance will fade with time.

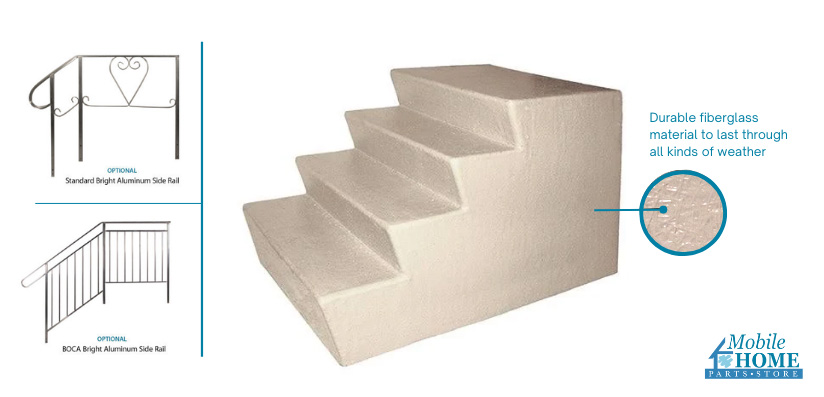

4. Fiberglass

Fiberglass is the best option for mobile home steps combining the best of both worlds. They are lightweight, affordable, and long-lasting. Fiberglass mobile home steps are constructed with a wood frame and covered in glass-fiber reinforced resin. Fiberglass is easily weather-resistant to water, wind, or sun, unscathed by damage.

Fiberglass mobile home steps are pre-textured with a slip-resistant stone-like surface for better footing in all types of weather. Unlike concrete or wood, they will not chip or rot over time. Most even include a handrail and pre-drilled mounting holes for easy installation. As a result, fiberglass mobile home steps are low-maintenance material and can last for decades.

Check with your local building codes to ensure your fiberglass steps meet the regulations for steps and handrails before purchasing.

Getting Steps for Your Mobile Home

When it comes to mobile homes, having the right steps can make all the difference. Whether you’re looking for a quick fix or a custom solution, there are two main options: premade or DIY steps. Let’s take a closer look at each to help you decide which is best for your home.

Premade Mobile Home Steps

Premade steps are ready-to-use steps that you can purchase from any reliable mobile home parts supplier. They come in various sizes, styles, and materials, making it easy to find one that fits your needs. Here are some pros and cons of premade steps:

- Convenience: Premade steps are quick and easy to install, saving time and effort.

- Variety: Premade steps come in various designs, sizes, and materials, allowing you to choose the option that best fits your mobile home and personal style.

- Durability: Many premade steps are made from durable materials like steel or fiberglass, ensuring they will last for years.

- Quality Assurance: You’re less likely to encounter issues like uneven steps or instability. Additionally, many manufacturers offer a warranty for a certain number of years.

However, there are also some drawbacks to consider:

- Limited Customization: While a variety of premade options are available, if you have specific design preferences or unique requirements, it might be challenging to find premade steps that meet your needs.

DIY Steps

If you’re the hands-on type and enjoy tackling home improvement projects, DIY steps might be the way to go. However, if you go the DIY route, it’s especially important to be familiar with your local building standards first. Here are some pros and cons of DIY steps:

- Cost-effective: DIY steps can be much cheaper than premade steps, especially if you already have some of the materials on hand.

- Customization: With DIY steps, you have complete control over the design, materials, and dimensions, allowing you to create steps that fit your exact needs and style.

- Sense of Accomplishment: Building your own steps can be a rewarding experience and give you pride in your home.

However, DIY steps also come with their own set of challenges:

- Violation of Local Building Codes: If your steps do not adhere to local building or HUD codes, all of your efforts could result in your steps being removed or even fined.

- Time and Effort: DIY steps can be time-consuming and require some skill and knowledge to build correctly.

- Risk of Errors: They may be less stable or durable than premade alternatives if not constructed correctly.

- Durability: Depending on your materials, DIY steps may not be as durable as premade steps.

Step Up with Dura Grip II™

Dura Grip II™ Fiberglass Steps are designed for your safety and comfort. They have a slip-resistant surface that exceeds industry standards. This surface ensures that you and your loved ones can safely navigate the stairs year-round, regardless of the weather conditions. These steps are built to last, with a durable construction that can withstand the test of time.

Standard and Deluxe Railing Systems

Dura Grip II™ offers both standard and deluxe railing systems that are compatible with their steps to enhance safety and aesthetics. These railing systems provide stability and support while adding a touch of elegance to your mobile home’s entrance.

- Standard Aluminum Side Railing: Install the standard railings when you need an economical choice. This railing features decorative spindles for a more upscale look.

- BOCA Aluminum Side Railing: Choose the Deluxe extruded aluminum railing for added strength and safety. It features vertical support beams, extra-wide handrails, and a specially designed grip for added security.

All rails meet or exceed most federal, state, and local code requirements. Check with your local officials for their particular needs.

Tags: mobile home parts, mobile home stairs, mobile home steps